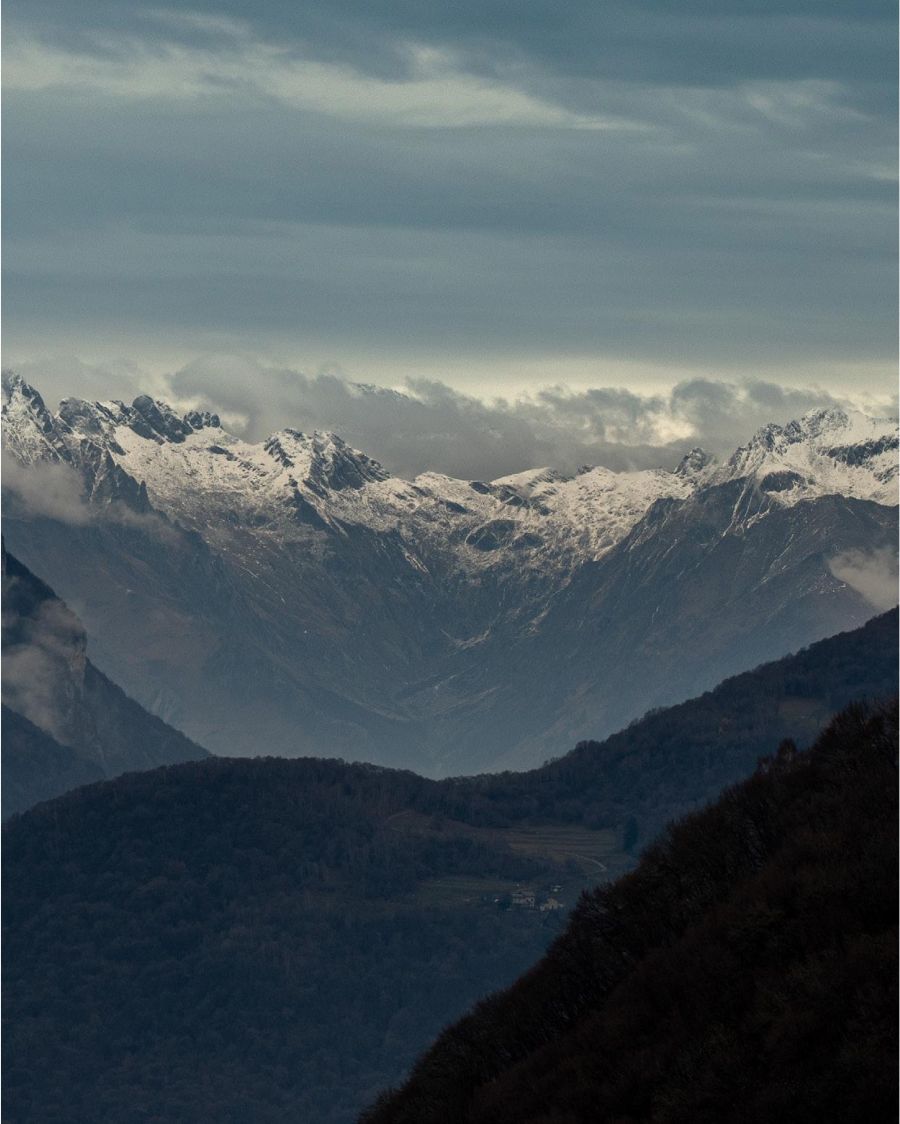

Morning light sits low over the mountains near the Swiss–Italian border. The surrounding terrain is defined by steady rises and falls, shaped gradually over time. For Sam and Andrew, it is more than scenery. It is where the first physical steps of their brand, and of the Buxton Automatic, are taking place.

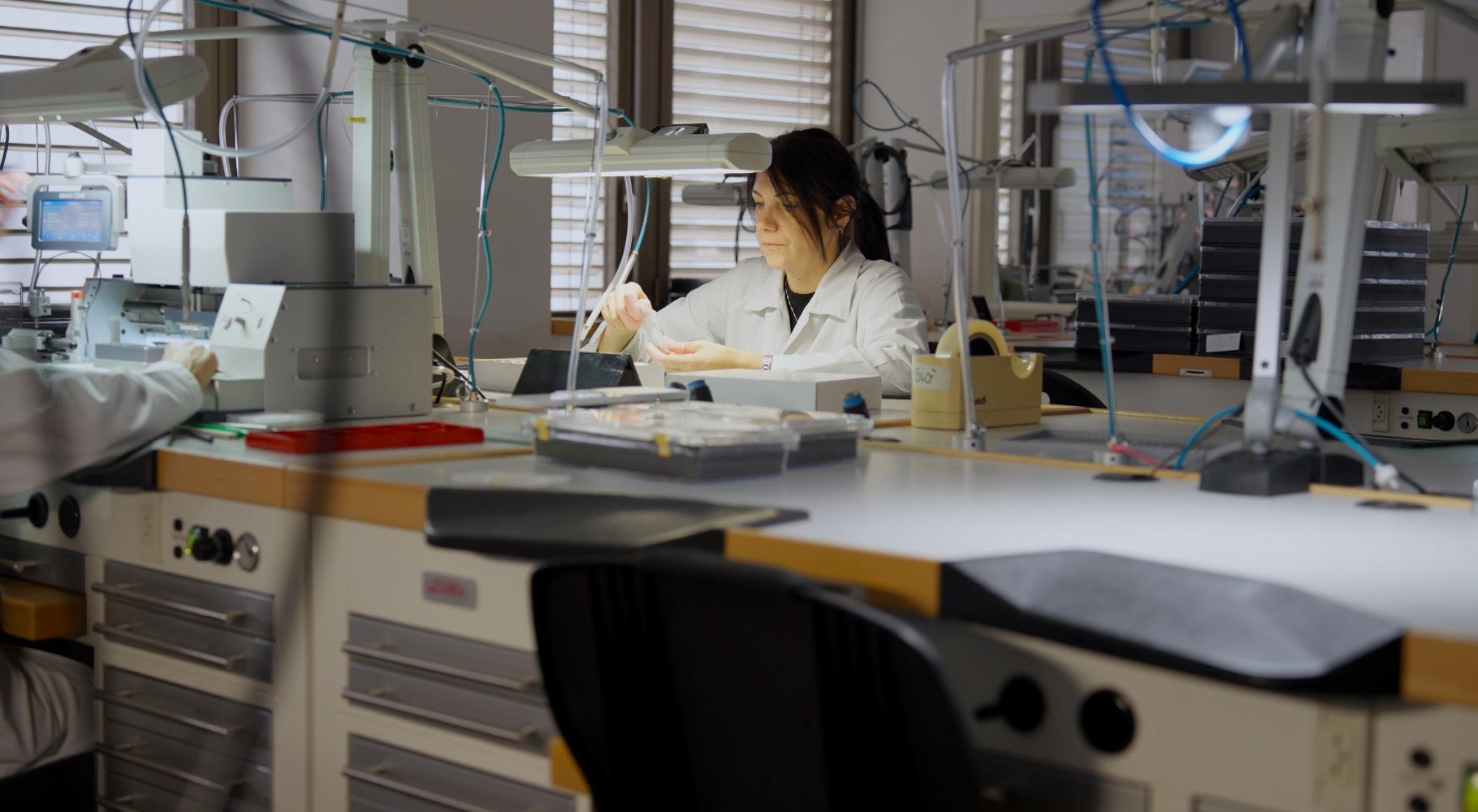

They have come to a family-run Swiss workshop, one with generations of experience, to see how early concepts are translated into finished components. This is where tolerances are checked, surfaces refined, and decisions made that will never be visible once the watch is on the wrist, but will determine how it performs over years of use.

As Sam and Andrew walk through the space, discussions stay focused and specific. They talk through alignment, feel, and the subtle differences that separate acceptable from exceptional. The Buxton Automatic is beginning to take its final form, assembled piece by piece with an emphasis on consistency and longevity rather than display.

Stepping back outside, the setting offers a quiet contrast. The surrounding light shifts through the day, reinforcing the principles guiding the project: restraint, clarity, and an approach to design that values function over excess.

The Buxton Automatic emerges from this combination of place and process— British founders working with Swiss makers in a region long associated with precision. It reflects not just where it is made, but how and why